HELICAL GEAR PUMP

| PUMP PROPERTIES | |||

| Q | : 1 – 350 m³/h | T | : 0 ~ 350 ºC |

| Hm | : 1 ~ 15 Bar | n | : 50 – 1500 d/d |

| Visc. | : 100 ~ 250.000 SSU | ||

Helical Gear Pump Types

Product Features

Helical gear pumps operate with high efficiency with gear pump principle. The pump shaft transfers the circular motion received from the motor to the other gear rotating in the opposite direction with the rotating gear on the shaft. As the gear are separated from each other, liquid fills between them. This liquid is transported to the discharge zone by the rotational movement of the gears and is transmitted to the discharge channel by the reunion of the gears. Depending on the viscosity of the fluid, pressures up to 20 bar can be achieved.

Owing to its helical gear structure, it is ideal for applications where silent operation is important and uninterrupted flow rate is required.

Use Areas

- Transport of motor oil, diesel fuel, gasoline, LPG, and diesel fuels

- In fuel filling and transfer systems

- In the safe transfer of chemical liquids such as acids, bases, and solvents

- In high-viscosity liquids such as polymers, resins, paints, and varnishes

- In dosing and mixing systems

- In the transfer of fluids such as molasses, sugar syrup, soap, and cream

Material Options

- Pump Casing, Covers, Gears: Cast Iron, Ductile Iron, Cast Steel, AISI 316 -AISI 316L SS

- Bushing: Bronze, Ball Bearing, Carbon Graphite.

- Sealing: Packing Gland, Mechanical Seal, Special Closed System, Cartridge Mechanical Seal

Working Principles

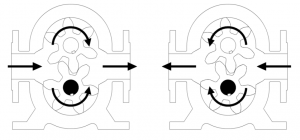

Picture on the side illustrates the entrance of space between rotating and rotated gears, passing by pump port. Black arrows shows pump’s rotation direction and progressing of the liquid inside the pump.

Pay attention to liquid progress in the gap between gears’ teeth and pump casing. Liquid is transferred not through the gears, but between each gear and pump casing. This picture illustrates the progress of the liquid up to pump discharge area.

In this figure, liquid is illustrated during filling all pump inner spaces and flowing out of the pump discharge port. Gears’ teeth mesh in and, thus, forces the liquid outside of discharge port.

Frequently Asked Questions

YILDIZ type pumps rotate clockwise when observed from coupling side. This direction is demonstrated with an arrow label placed on pump. By running for a very short period, pump rotation direction should be checked for following direction of the arrow.